Carpenters still learn them: wood joints to connect beams when building. The different ways to connect beams and construction timbers are huge. Starting with simple overlays, through slot and tenon joints to complicated corner joints such as the oblique and concealed corner sheet or the hook sheet.

But what is traditionally conveyed to the young carpenters is almost a whole book for the do-it-yourselfer, because of course to connect beams when building, you need a lot of practice and knowledge in making these connections. And so today these artificially sophisticated connections are often replaced by modern metal connectors.

The use of these structural steel sheet-formed hardware saves a lot of working time compared to conventional construction methods, and the skill of the fabricators is not so great. In addition, in contrast to the above-mentioned old joining techniques, it is sometimes possible to reduce the wooden dimensions when using modern fittings.

In any case, they make it much easier for the do-it-yourself maker to do all the wood connections and connect beams when building. He can build garden houses , conservatories, carports, patio roofs, screens or pergolas without special knowledge with these practical fittings .

For the different forms of wood connectors, there are also very versatile applications. We have summarized the types of connections here in four groups, so that it quickly becomes clear which connector is good for what.

All wood connectors are made of sheet steel, cut to size, shaped and pre-drilled for mounting. The smaller holes – 3.5 or 4.5 mm in size – are designed to stop with galvanized special nails (V-anchor nails).

These nails are available in six lengths from 40 to 100 mm and in thicknesses of 3.1, 4 and 6 mm. They are offered as well as the fittings in wood specialist markets and hardware stores.

Some fittings such as the perforated plates and the perforated plate have small holes for nails, while others, such as the angle connectors or bar shoes, have larger holes of 11 or 13.5 mm in diameter for galvanized hexagonal wood screws in addition to the particularly strong attachment.

Find more carpentry guides, tips and advice

Classic ways to connect beams when building

This is how the old masters would have done it, or is still being restored in half-timbered construction. The lower stand receives a cone that is about as wide as a third of its material thickness. The length of the cone is about 5 to 6 cm, whereby of course the material thickness of the beam on top must also be taken into account.

The lying beam is then given a slot accordingly. If another beam is placed on top, this is provided with an overleaf of about 2 to 3 cm depth and thus a form-fitting connection is established.Flat connections

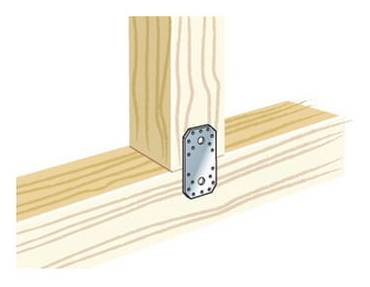

Flat connector

Flat connectors in heavier design are 2.5 to 3 mm thick, 96 to 180 mm long and each with holes for nails and screws.

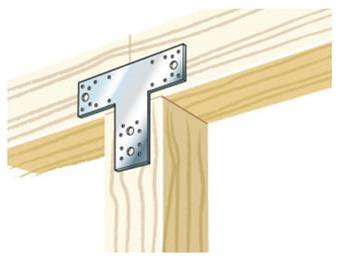

T-flat connector

T-flat connectors are equipped with holes for nails as well as for hexagonal screws. You can get them in sizes 80 x 86 x 2 mm and 160 x 98 x 2.5 mm.

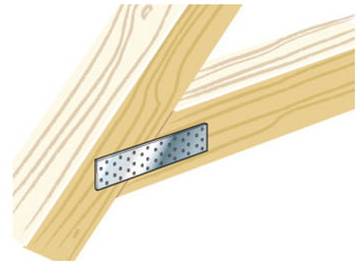

StHole plates

Hole plates are used to bridge long distances. They can be obtained in a length of up to 400 mm, perforated plate strips even in up to 1250 mm.

Angular connections

StSimple Angle Connectors

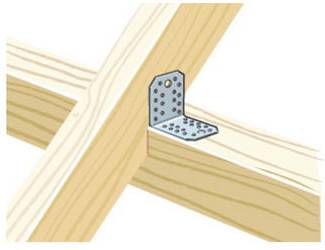

Simple angle connectors are made in 2 mm thickness and are available in dimensions from 40 x 40 x 20 mm. They are used for light connections, such as when mounting a roof slat.

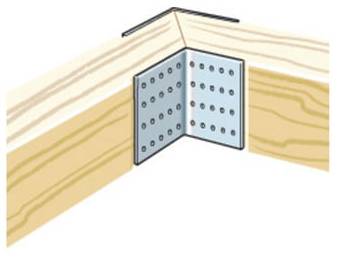

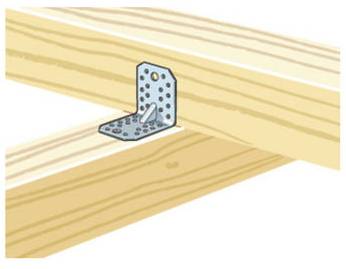

Hole plate angle horizontal

Hole plate angles are, so to speak, the larger siblings of the angle connectors. In dimensions ranging from 40 x 40 x 60 mm to 100 x 100 x 100 mm, powerful beams can be connected in both the vertical and horizontal plane.

Hole plate angle vertical

Hole plate angle vertical

Angular Connector

Angular connectors in strong design are created for a similar range as the above-mentioned perforated plate angles, but are offered with large holes for hexagonal screws.

Heavy-duty angle connector

Heavy-duty angle connectors also have a beading for greater stability, making it almost impossible to bend the angle.

Long hole angle connector

Long hole angle connectors are perfect when hexagonal screws are used as through screws with counter nut.

Bar connections

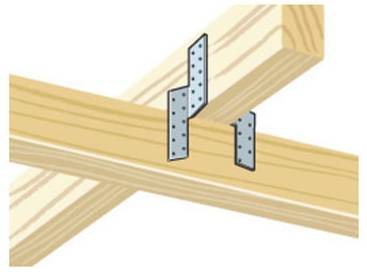

Rafter anchors

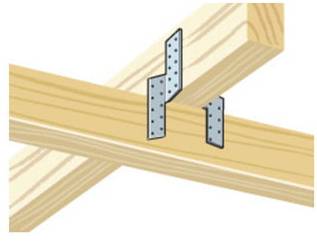

Rafters anchors are ideal for connecting two levels. Used on both sides, they hold up beams perfectly together. Rafterpfettenankers are usually 2 mm thick and their thigh width is 33 mm. The lengths vary from 170 mm to 330 mm.

Heavy-duty angle

Heavy-duty angle connectors are not only used for L-shaped connections, but also for beams running over crosses. For these bar connections, make sure that an upper bar is always on a lower one. This means that a beam is never screwed under.

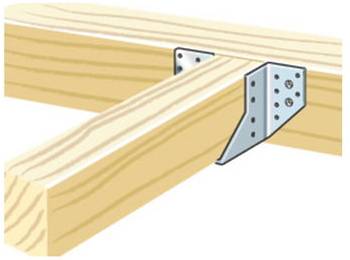

Beam shoe

Beam shoe with external tabs, called type A. If a beam hits another crossbar bluntly, a beam shoe must be used. The beam is then stored in the metal connector. The screw or nail connections thus only experience disdriver forces and no tensile forces. You get them for beams from 40 to 160 mm width.

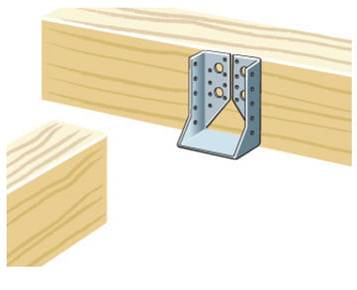

Beam shoe with internal tabs

Beam shoe with internal tabs, called type B, is used when as little of the metal is to be seen. However, is less torsional stiffness than the type A variant.

Vario Beam shoe

Two-piece Vario beam shoe can be infinitely adjusted and is particularly interesting for the use of wood probes. For beams from a width of 50 mm.

Slanted fixtures to connect beams when building

Strut Connector

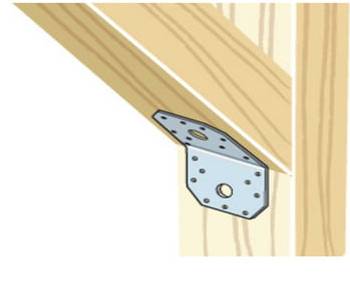

Strut connectors, also known as headband connectors, have a prefabricated 135-degree angle. With this slant, pergola and roof struts can be easily fixed. Such strut connectors are also available at adjustable angles. Here the middle is punched in and any angle can be bent. Available in sizes from 50 x 50 x 40 mm to 90 x 90 x 65 mm.

Multipurpose Connector

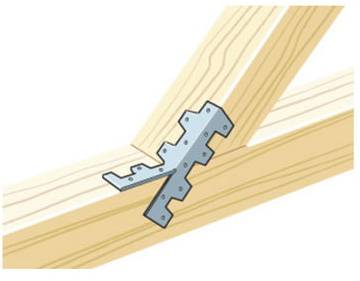

Multi-purpose connectors: Due to their design with the slit thigh ends, these connectors can be bent into almost any inclination. With a thigh length of 40 mm, they have a total length of 120 mm and a thickness of 2 mm.

Rafter anchor

Rafters anchor, here in their main task, namely the connection of rafters (slanting beams) and pfette (straight running beams). The rafter must be cut out at the appropriate angle so that it can connect to the pfette in a form-fitting manner. This recess, which has to be worked out with a hand saw or a hand keis saw, is called Kerve. The rafter seam anchors are then fastened with anchor nails (groove or comb nails).

Hole plate angle rafters

Hole plate angles can also be used as connectors of rafters. It is important that the angles are always fixed on both sides.

Tips for processing

- Nails: Always use so-called comb nails as fastening material. These are nails with a fluted surface, which interlock well in the wood. Spax screws should not be used as they are rather brittle in material and do not withstand shear forces well, so they simply break under high loads.

- Distance from the edge: Always select the metal angle connector 1 to 2 cm narrower than the wood to be connected. This way you can make sure that the nail distance of at least 2 cm to the edge is maintained. This nail distance is good to pay attention to, as in the worst case the wood bursts away at the edge, the nail no longer gets a hold and you have to change the beam.

Gerhardt Richter is a writer and a trainer at trade technical colleges, specializing in carpentry, plumbing, mechanics and construction.

Gerhardt Richter is a writer and a trainer at trade technical colleges, specializing in carpentry, plumbing, mechanics and construction.