Reeds are a natural product that grows on the banks of shallow waters. When dried, the robust plant stalks have been used for thousands of years to cover traditional thatched roofs. In many historic buildings as well as in modern eco-construction, however, reeds also play a major role in other (invisible) places: as a stabilizing fabric in flush-mounted buildings. Our guide shows how to use reed mats to build sustainably.

The often heard term reed tissue actually gives a false impression. Under a fabric, one imagines a fabric of fine threads. Reed tissue, on the other hand, is a mat made of dried plant stalks, which are at least between five and ten millimetres thick. The word reed fabric therefore actually fits better. Or you can leave the term “tissue” completely out and speak of a plaster carrier mat. The term reed stucco is also common.

The flush-mounted mats, which are available in specialist stores as rolled goods, are bound together from 70 to 80 stalks per running metre. As a connecting element for the horizontally arranged reeds, most of the galvanized wire is used. In addition, there are also sight and sun protection mats made of reeds for the garden and balcony. For these products, however, the number of stems per running meter is higher.

Use reed mats to build sustainably: Typical applications

The mats are delivered as rolled goods.

Before there were reinforcement mats or reinforcement fabrics made of metal or plastic-coated glass fiber, reed fabric was a common plaster carrier material. Today it is primarily found as a historical building material in the preservation of monuments. In addition, the alternative plaster carrier made from renewable raw materials is appreciated by ecologically minded builders – especially in clay construction.

In principle, the mats can be used both indoors and outdoors. However, since they are mostly processed together with the classic interior plasters on a clay, lime or plaster basis, the application is ultimately carried out mainly indoors. In combination with lime plastering, it is also possible to use it outdoors, for example on the facade. Clay and gypsum plasters, on the other hand, are too sensitive to moisture for components that are exposed to regular weathering.

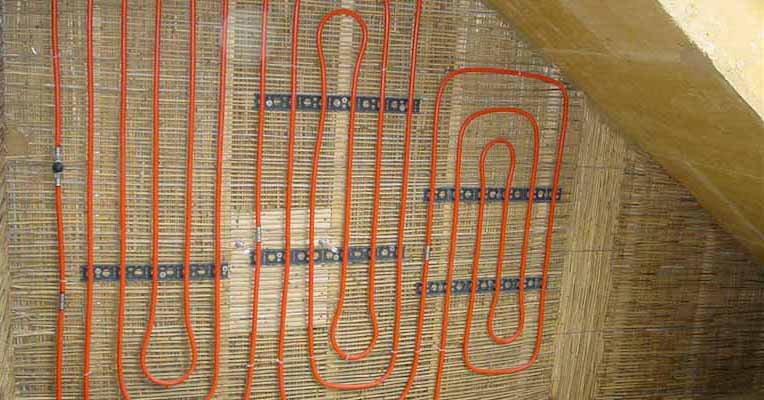

The reed fabric is mainly used for smooth surfaces, on which thicker plaster layers could easily fall off without reinforcement. This is the case, for example, with wooden formwork, wooden beams, OSB boards and plasterboard.Unlike the reinforcement fabric of a WDVS facade, which is only loosely placed in the fresh plaster, the reed support is first attached to the substrate and then first plastered.

Construction of the mats

The binding wire is wrapped around the individual stalks and the clamping wire.

For plastering a simple wall when you use reed mats to build sustainably, the manufacturers usually recommend the standard 70-steel fabric. For higher requirements – for example, when plastering sloping roofs, curves or ceilings, there are also denser fabrics with 75 to 80 stalks per running meter.

The premium mat consists of particularly stable and straight stalks of Turkish origin with a diameter of up to 1 cm. The distance between the individual stalks is (depending on the product) two to five millimeters. Inferior reed tissue can be recognized, among other things, by the fact that half and broken stalks were used, which are also usually very brittle and have a gray coloration.

The stems are held together by galvanized wires. Here, too, there are differences in quality. Inferior wires have a thinner galvanizing layer and are therefore more prone to rust. Functionally, the mats have two different types of wire: the thinner binding wire is wrapped around the individual stalks as well as around the slightly thicker clamping wire (see photo). The latter is also referred to as a wire running wire.

Processing

The mats are usually fixed using galvanized clamps, which are attached to the running wire and tackered to the substrate. The fabric must be laid in such a way that the wire points in the direction of the processor. The upper and lower ends of the wires are twisted together after laying, so that the tissue binding can no longer dissolve later.

During plastering, the mortar mass is pressed between the reed stalks, so that a firm claw ingestion takes place between the plaster and the mat. The high flexural strength of the reeds ensures a stable load-bearing capacity even with thick plaster layers. The clamp fastening strengthens the adhesion tensile strength of the plaster-reed composite.

The plaster application is carried out in several layers in layer thicknesses of a maximum of 15 mm. Before applying each new layer, the surface of the underlying layer must be completely dry. The number of layers varies in practice – depending on the desired flush thickness. In the last layer, the processor may insert an additional reinforcement fabric if necessary when you use reed mats to build sustainably. The finish is followed by a decorative top plaster, which can also be painted if required.